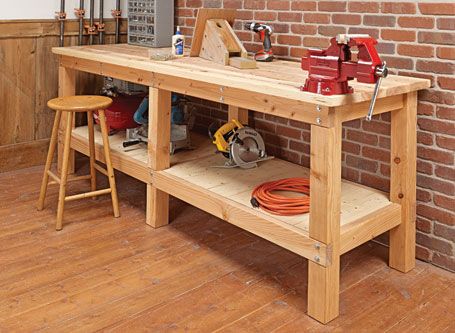

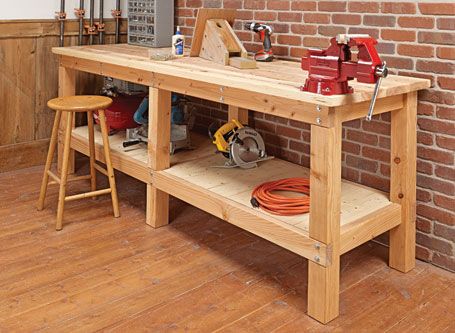

Workbenches | Common DIY Mistakes People Make with Their Workbench

Workbenches are an incredibly useful thing to have at home. But people often make mistakes with either the assembly or the use of their workbenches.

Common Mistakes That People Make

Too Many Woodworking Vices

A surprising number of people install far too many vices on their workbenches. Ideally, you should have one face vice and one tail vice. Installing a vice at every corner of the workbench – unless it is specifically required – is time-consuming and pointless.

Too Many Dog/Holdfast Holes

If your workbench has a tail vice, it will require a row of closely spaced dog holes near the front of the benchtop.

If you use holdfasts, you will need holdfast holes (about 8).

You don’t want to overdo it when putting dog/holdfast holes, it will not necessarily make the bench weaker. But will take a lot of time to execute.

Over-Agonising the Standard Workbench Height

The best thing to do to choose the height of your workbench is to choose a height between your tight and waist that seems right. You’ll get used to whatever height it’s at as long as it is in between these two points so there is no need to worry. If you are really uncertain about it then make it a little higher and trim the legs down to an appropriate height once it’s built.

Making the Bench do Crazy Tricks or Store an Arsenal of Tools

A workbench does exactly what it says on the tin. It is a bench, for working at. Many people make the mistake of using workbenches to store and display too many tools. If you do this, then you may want to consider getting a joiners table. The work surface should be flat and stable, without an accumulation of tools.

Building the DIY Workbench Too Deep

If your workbench is too deep (e.g. 48”) then it is a lot less useful. The benchtop should be shallower than your casework, this will make it easier to work on the casework.

Choosing the Wrong Tools to Build Your Workbench

Choosing the right tools to build your worktop is essential. Some things that you want to achieve may require a powered joiner and planer. If you try and do it by hand it will be incredibly tedious.

Worrying Too Much About Wood Movement and Benchtop Flatness

It’s important to remember that no matter how much you try to get your workbench as flat and stable as possible – you probably won’t be able to make it perfect. If there is an issue with the movement or flatness of your workbench that is caused over time, it can be fixed really quickly (in about 45 minutes)

Solution

The ultimate solution for building or using your workbench wrong is to buy one that is tailored to your space and your needs. A professional in industrial equipment can assist you from start to finish.